| | Microchip-Systems for In-situ Electron Microscopy of Processes in Gases and Liquids Techniques allowing real-time high resolution imaging of nanoscale processes by in-situ TEM are currently under rapid development[1] based on microchip systems that enable real-time imaging of controlled processes to be combined with, for instance, correlated electrical measurements[3-4]. As well as gas phase ETEM studies, microchip based systems also allow imaging of processes in liquids with good resolution [5-8]. Here we report on our recent advances in joule heated microcantilevers used for gas phase in-situ TEM studies of nanowire devices [3-4] and on our efforts in creating a suspended microchannel system for TEM imaging of liquid samples and processes [12].

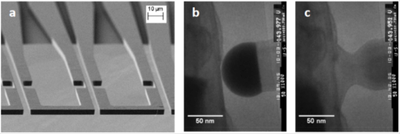

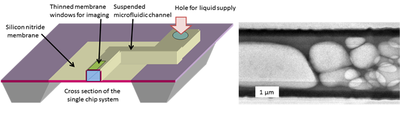

We created and characterized nanowire devices by growing silicon nanowires in-situ TEM using the VLS mechanism [9], from one joule heated microcantilever to an adjacent cantilever, thereby forming a bridge as shown in Fig 1a. Building on our previous experiments[3-4] we studied the details of contact formation when a hot nanowire grows into contact with a similarly heated adjacent cantilever. An example is shown in Fig 1b, where a silicon to silicon junction forms as the catalytic gold diffuses away. The suspended microcantilevers system opens up novel ways to create electrically contacted nanowire devices [10] in addition to allowing in-situ TEM studies of the many simultaneous processes taking place upon contact formation and in-situ electrical measurements carried out after connected nanowires were formed.

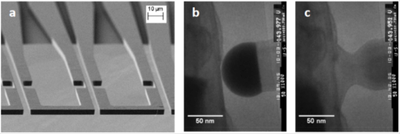

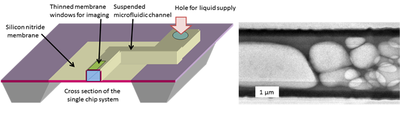

To study liquids encapsulated between membrane windows on microchips, the reported microchip devices today all involve two bonded chips with thin membranes of silicon dioxide or nitride [11]. To allow better control of the encapsulated volume and geometry, we are exploring devices using monolithic chips with suspended microfluidic channels made from silicon nitride. On the channels, thinned window regions allow higher resolution than in the supporting part of the channel. Figure 2a shows a sketch of such a microchip system and Fig 2b presents a first demonstration of the system with a liquid sample mixed with microscopic gas bubbles in a 1 µm high and 4µm wide channel. The system’s novel geometry is expected to improve the imaging resolution by providing precise control over the channel height and the possibility of achieving small regions with ultrathin membranes for the best possible resolution. We have also developed an electrochemical setup suitable for use in SEM [13].

Figure 1. (a) SEM image of suspended monocrystalline silicon cantilevers. Joule heating of adjacent cantilevers makes in-situ TEM VLS growth possible in disilane gas using eutectic particles formed from a thin film of gold deposited onto the cantilevers. (b) TEM image of a silicon nanowire about to reach the side wall of an adjacent heated cantilever, and, (c) the subsequent formation of a silicon–silicon junction as the catalytic gold diffuses away.

Figure 2. Schematic cross section of the suspended microfluidic channel system for liquid phase TEM imaging. The silicon nitride microfluidic channel crosses a silicon nitride membrane providing mechanically stable suspension. Thinned regions in the channel allow locally improved resolution. The composite overview TEM image shows a mixture of air bubbles and water in a channel [12]. References:

[1] F. (Feng) Tao et al., Science, vol. 331, Jan. 2011, pp. 171 –174.

[2] J.B. Wagner et al., Micron, vol. 43, Nov. 2012, pp. 1169–1175.

[3] C. Kallesøe et al., Small, vol. 6, 2010, pp. 2058–2064.

[4] C. Kallesøe et al., Nano Letters, vol. 12, Jun. 2012, pp. 2965–2970.

[5] M.J. Williamson et al., Nature Materials, vol. 2, 2003, pp. 532–536.

[6] A. Radisic et al., The Journal of Physical Chemistry B, vol. 110, Apr. 2006, pp. 7862–7868.

[7] D. Li et al., Science, vol. 336, May. 2012, pp. 1014–1018.

[8] H.-G. Liao et al., Science, vol. 336, May. 2012, pp. 1011–1014. |