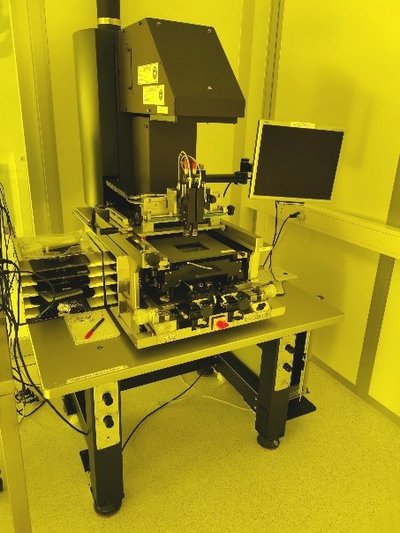

Overview:

The EVG610 is a highly flexible research and development system that can handle small substrate pieces and wafers up to 100 mm. It supports a variety of standard lithography processes, such as vacuum-, soft-, hard- and proximity exposure mode, and allow front-side and back-side alignment.

Applications:

Mask aligner for alignment and UV exposure of resist coated substrates. It patterns photoresists. The patterns are subsequently transferred into structural elements using other instruments in the facility.

Specifications:

Alignment resolution: 0.5 µm

Pattern resolution: <0.8 µm in vacuum contact, ≥ 2 µm in proximity

Mercury arc lamp: 500W Near UV

Mask size: 5 inch

Wafer diameter: Pieces and 100 mm wafers.

Superuser:

Bjarke Rolighed Jeppesen